Current¶

This document describes the design considerations and implementation details for the current card. A block diagram is presented and each component is discussed in detail. Specifications of each component are provided based on the datasheet.

Relevant Hardware Versions¶

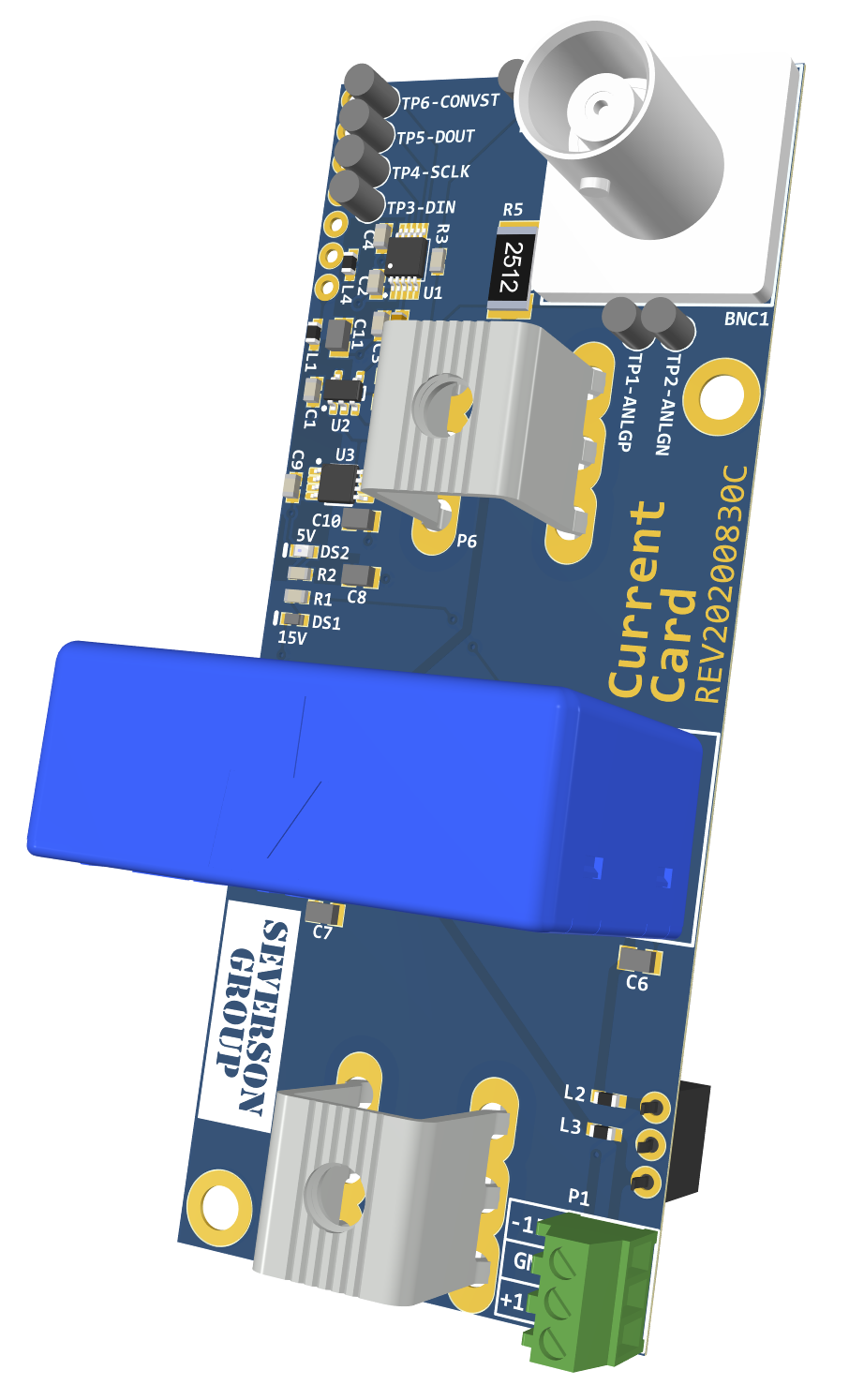

REV C

Design Requirements and Considerations¶

The current measurement card was designed to the following specifications:

Current measurement range of +/- 55A (rms)

Noise immunity

Quick adjustment of the sensing range

High sensor bandwidth

SPI output to interface with the sensor motherboard

Block Diagram¶

The high level block diagram of the current sensor card is shown below:

Current Sensor¶

LEM LA 55-P current sensor is selected for this design, as it is the only sensor available from LEM with an open aperture and PC pins that can measure +/-55A. The open aperture was a requirement as it allows for the range to be easily scaled down just by adding turns to the primary. The LA 55-P is a closed loop compensated hall effect transducer that has an accuracy of +/-0.65% and linearity of <0.15% which is quite good compared to other sensors from LEM. It has an excellent bandwidth of 200khz and a low impedance current output that is inherently more immune to noise than a high impedance voltage output.

Burden Resistor (RBURDEN)¶

A burden resistor (R5) is used to convert the current output of the sensor to a voltage. For a sensing range of 70A, the burden resistance, RBURDEN was calculated using the following equation

VBURDEN = (N1/N2) IPRIMARY RBURDEN

RBURDEN = (10 V/70 A)*(1000/1) = 143Ω

The LA 55-P datasheet specifies the burden resistor value must be between 135Ω and 155Ω so a 150Ω resistor was selected.

Current Sensor Gain¶

The LA 55P has a conversion ratio of N1:N2 = 1:1000, where N1 is the primary turns (the number of turns the user passes through the sensor’s window) and N2 is the secondary turns. With the chosen RBURDEN and N1 = 1, the current sense circuitry has a current-voltage gain of 1/7 [V/A].

To use the sensor in a lower current range, the user can increase the number of primary turns without the need to modify any other parts of the circuit. As an example, to sense currents in the range of +/- 7 A, N1 = 10 can be used.

Voltage Reference (LDO)¶

The voltage reference, VREF is needed for the ADC. As 5V is readily available, and the LDO will have a minimum drop out voltage, VREF = 4.5V was chosen (beginning with board revision C). The LDO selected was REF5045 from Texas Instruments, which can take a 5V input and provide a 4.5V reference output. This has an accuracy of 0.1% and low noise of 3μVpp/V.

Op Amp Stage¶

A non-inverting level translation circuit is implemented using Op Amps as shown here:

This circuit is used to translate the voltage across the burden resistor, which is bipolar (voltage span includes both positive and negative voltages), to the ADC input range of 0-\(V_{\rm REF}\).

The output voltage for this circuit can be solved as:

A more precise expression for \(V_{\rm BURDEN}\) can be derived as:

The resistor values can be calculated from solving these expressions analytically. However, the algebra gets quite complicated. Instead, these values were computed using the TI analog engineer’s calculator.

The final design is implemented so that \(I_{\rm PRIMARY} = -70A\) results in \(V_{\rm out} \approx 0V\) and \(I_{\rm PRIMARY} = 70A\) results in \(V_{\rm out} \approx 5V\).

Attention

As the op-amp output voltage approaches the supply rails, it tends to distort and behave nonlinearly. It is recommended to limit the output voltage to stay within 0.2V to 4.5V for best performance. The user is advised to consider their required current measurement range with the final voltage expressions to select an appropriate number of primary turns.

First Order Anti-Aliasing Filter¶

A first order RC filter is implemented on the output of the op amp circuit. The cutoff frequency was set at 48kHz and the following equations was used for the computation:

Note: The cutoff frequency can easily be changed by swapping out R3.

Analog to Digital Converter¶

A single-ended ADC was selected. The ADC used is the Texas Instruments ADS8860. It is a pseudo-differential input, SPI output, SAR ADC.

The maximum data throughput for a single chip is 1 MSPS but decreases by a factor of N for N devices in the daisy-chain.

The input voltage range is 0-\(V_{\rm REF}\). The positive input pin of the ADC AINP is connected to the output of the low pass filter, and the negative input pin AINN is connected to GND.

Relationship Between Input and ADC voltage¶

From the equations provided in the Op Amp Stage section, the general relationship between the measured current \(I_{\rm PRIMARY}\) and the input voltage of ADC \(V_{\text{ADC}}\) can be calculated, and the relationship for each revision of the current sensor board is provided below:

General Expression¶

Revision A, B¶

In this design, N1:N2 = 1:1000, \(V_{\rm REF}\) = 5V, \(R_{\rm BURDEN}\) = 150Ω, \(R_{\rm a}\) = 10kΩ, \(R_{\rm b}\) = 8.45kΩ, \(R_{\rm c}\) = 4.64kΩ, resulting in:

Revision C¶

In this design, N1:N2 = 1:1000, \(V_{\rm REF}\) = 4.5V, \(R_{\rm BURDEN}\) = 150Ω, \(R_{\rm a}\) = 10kΩ, \(R_{\rm b}\) = 10.7kΩ, \(R_{\rm c}\) = 4.12kΩ, resulting in:

Connectors¶

There are two screw terminals

P5andP6to connect the conductor in which the current is to be measuredA screw terminal block

P1is used to connect the +-15V supply for the current sensorA BNC terminal is available to directly measure the output across the burden resistor RBURDEN

Footprints¶

A user may want to change some of the passive components based on the range required and the RC filter cutoff frequency desired. The footprints of passive components that may need to be replaced i.e, the burden resistor (R5), the resistors in the Op Amp stage, and the RC filter components is provided here for quick reference. Note that these footprints are imperial codes and not metric codes.

Component |

Footprint |

|---|---|

R3 |

0603 |

R4 |

0603 |

R5 |

2512 |

R6 |

0603 |

R8 |

0603 |

C5 |

0603 |